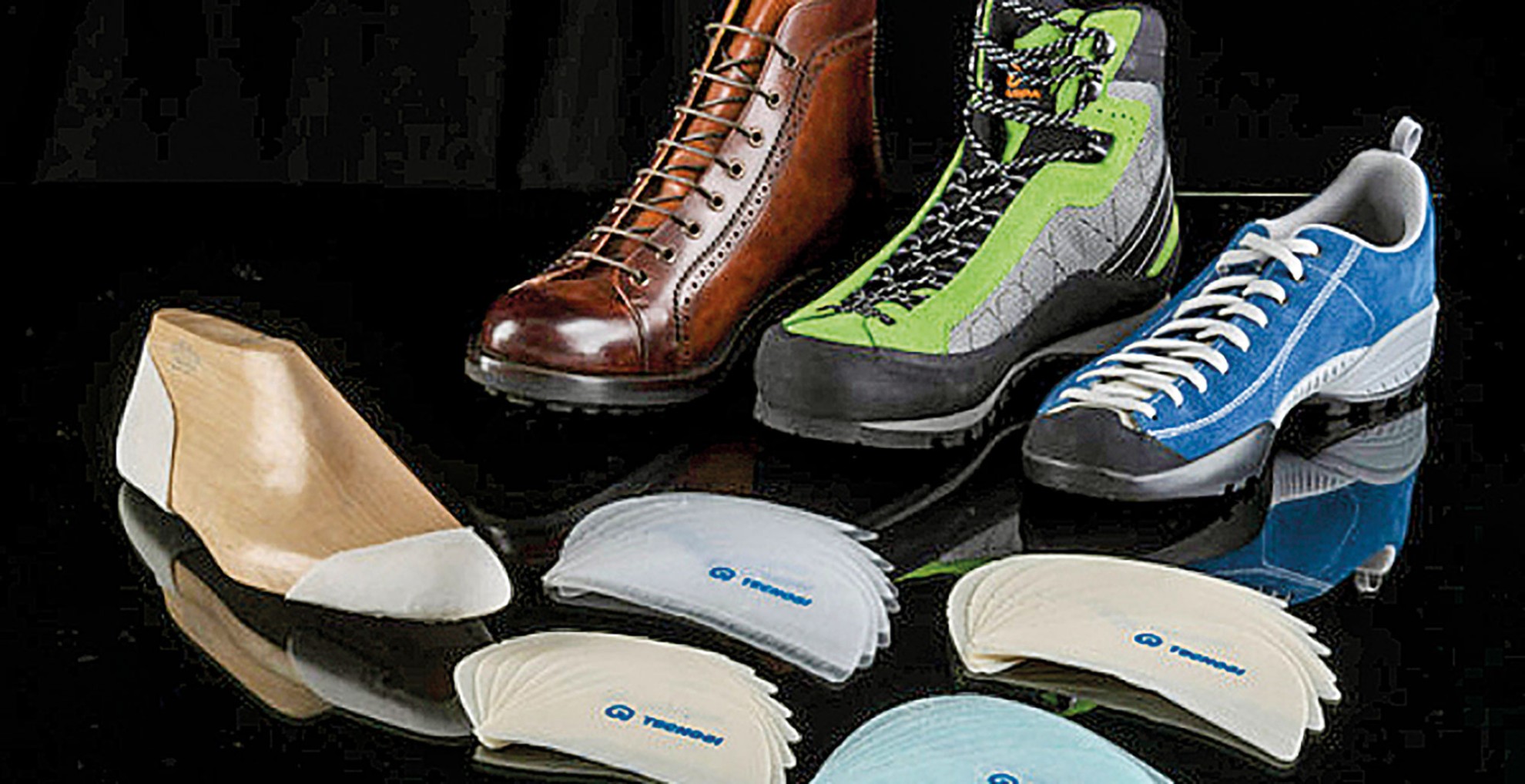

With 42 years of experience in the production of ferrules, counters and thermoadhesive reinforcement fabrics for footwear and manufactured goods, TECNOGI has managed to offer innovative proposals in terms of functionality and now more than ever focused on preserving the environment and sustainability.

With industrial plants in Italy and China, and commercial representatives around the world, TECNOGI supplies the international industry of 70 countries on all continents with innovative products that contribute to the final quality of footwear.

Constant research and search for new raw materials and continuous technological upgrading have succeeded in obtaining differentiated and specific components for each type of footwear, compatible with current health and eco-environmental needs.

It is an extruded material with a “ping-pong” effect that comes in a soft and a hard version, both with a traditional EVA-based adhesive or a polyurethane adhesive with two supports. Its application is carried out by a pneumatic press, equipped with a hot curved plate, timer and thermostat.

The recommended working temperature is between 130 and 150ºC and the contact time is between 6 and 12 seconds, depending on the thickness of the material. However, it is suggested to carry out a preliminary test to verify the results based on the characteristics of the upper.

The TALYN toe line is environmentally friendly because it is made from recyclable materials and production waste is regenerated and recycled in the production process.

Material produced by extrusion of copolymers, with exceptional mechanical characteristics, which adapt to all footwear that require high resistance and long-lasting retention. It can be used by preheating the material before inserting it, or by placing it cold between the lining and the upper.

In the first case, on a Teflon plate (or another heat source) at a temperature between 70 and 80ºC it softens quickly. Since the polymeric compound is not tacky, the operator can manually insert the counter between the lining and the upper.

In the case without preheating, the buttress is manually placed between the lining and the upper, and is formed using the machine to mold the back, at a temperature between 140 and 150 ° C for 10 to 15 seconds. For two-units machines, cold stabilization allows a perfectly shaped counter to be obtained.

Like the toe caps, RELION materials are also environmentally friendly and recyclable.

To complete the sustainable offer, TECNOGI has the biodegradable articles BIOREL and the renewable TECNOSOFT.

RELATED ARTICLE:

- TECNOGI: Production of sustainable toe caps and counters