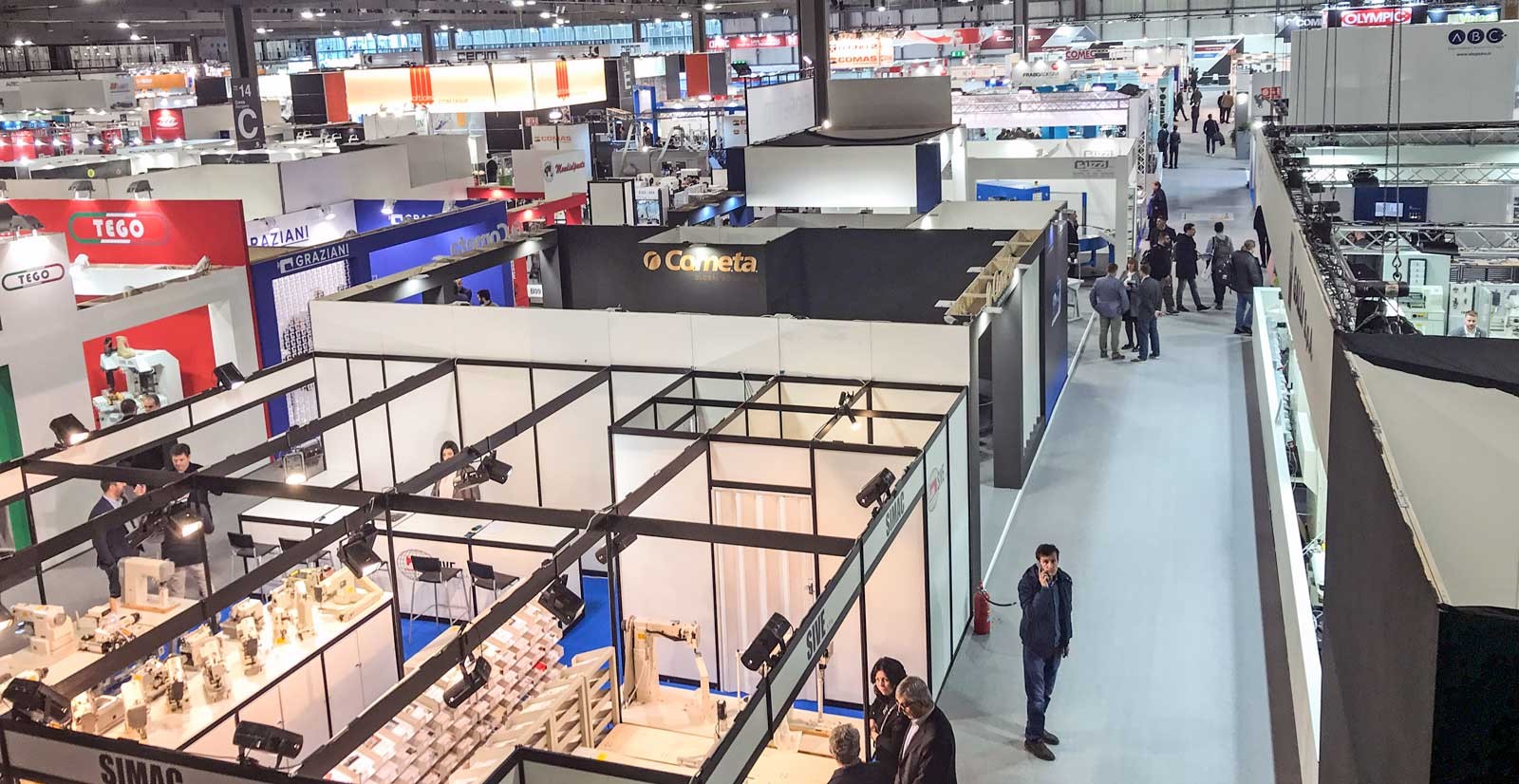

The health emergency that broke out after the SIMAC-TANNING TECH fair in Milan, at the end of February 2020, in a period when operators were busy reaping the positive benefits of the high number and quality of visitors, suddenly stopped the supply chain in the entire fashion sector.

In the last days, all the efforts made previously with a view to Industry 4.0 were important, because they contemplate the technology capable of supporting companies and exports on the one hand; while on the other, they will allow a quick recovery to be implemented when activities are restarted.

But let's go by order and go back to February 19, 20 and 21, 2020, where in the hallways of Halls 14 and 18 of SIMAC-TANNING TECH, were present the main suppliers of technology for footwear, manufactures and tannery.

Data management and optimization of production cycles represented one of the important aspects within the companies' proposals. However, sustainability continues to be the main theme, which is at the forefront at the fairs MICAM of Footwear and MIPEL of leather goods, and with the same notoriety at LINEAPELLE of materials and components, and SIMAC-TANNING TECH.

Thus, the brand call had the desired effect. The launch of numerous marketing campaigns, where major fashion names challenged each other, promoted increasing attention to sustainability across the chain.

Machine manufacturers have certainly not backed down on this purpose, but have relaunched new bets: Along with the solutions developed on previous ideas and perfected, there were new projects and innovative full production models.

The course is marked by the 5 "R": Rethink, Reduce, Reuse, Recycle and Recover. Along with digital technologies that allow programmed control, measurement and intervention. Finally, the improvement in the conditions of the workers is an aspect strictly related to comprehensive sustainability.

If in the past decades technological flexibility was the most sought after objective to face the change in the markets, today the winning team is the integration between materials-technology and processes. Companies can no longer afford to find new solutions without coming into symbiosis with the other actors involved.

The fulons used in the wet stage of tannery work with properly formulated chemistry and recipe.

The precision and quality of the subsequent mechanical operations on the skins are carried out where the analysis and controls allow the repeatability of the process.

Energy consumption and sustainability during the drying and finishing of the hides are solved through an integral correlation between technologies, products and functional parameters.

Finally, the proposals for custom prints and designs are strengthened, based on innovative materials and advanced application systems.

Among the machines and equipment for footwear and leather goods, there continues to be a strong evolution in the digitization and automation of cutting systems, the use of robotic islands and the simplification of shoe assembly systems.

The industrialists of the sector, on the one hand, look for technology to update themselves after postponing decisions, and on the other hand, to find original solutions that can guarantee the quality and innovation of their products.

Digitization not only means greater control of processes, it also enables a smooth organization of work, which are fundamental aspects for companies that must supply fashion products in real time to the market, to satisfy the requests and wishes of customers.

The transformation is underway, so much so that some proposed solutions try to anticipate what the future of footwear and the leather chain will be.

With SIMAC-TANNING TECH leading this trend, technology providers are waiting for the opening of borders and the recovery of markets to implement their ideas, which for now are on hiatus due to the spread of the virus.