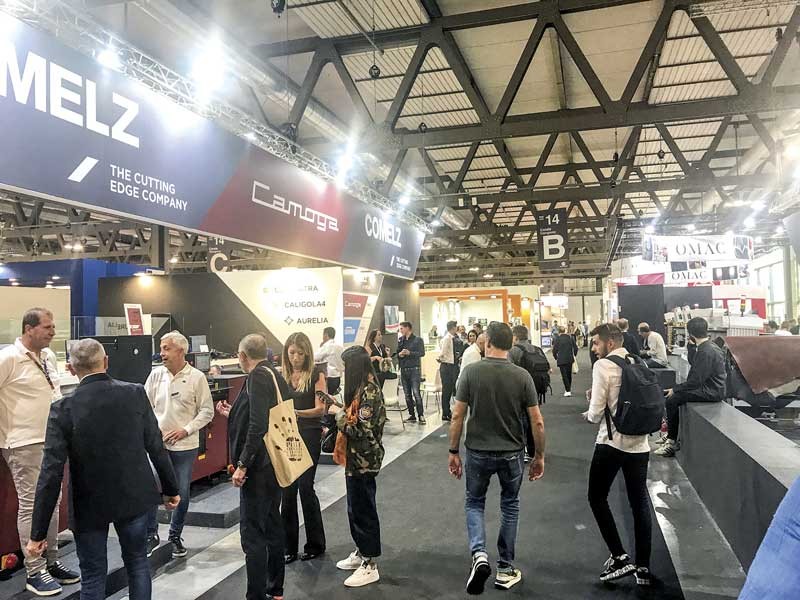

The International Exhibition of Machines and Technologies for Footwear, Leather Goods and Tanning Industry took place between September 20th and 22nd at Fiera Milano Rho. The event shared a location and date with LINEAPELLE, an exhibition dedicated to skins and leather, materials, components and accessories for the fashion industry; while it was also part of the set of exhibitions carried out under the hashtag #finallytogether, where MICAM of finished footwear, MIPEL for leather goods and HOMI for fashion clothing and accessories, participated.

In the 13,000 square meters of pavilions 14 and 18 of the fairgrounds, machines, equipment, systems and services from more than 280 exhibitors were exhibited, with the common idea of environmental, social and economic sustainability, through productive ecosystems.

Throughout the event, 4 thousand visitors attended, more qualified and relevant than the previous edition, from 86 countries, including Mexico, Brazil, France, Spain, Portugal, Germany, India and Turkey. Asian attendance was very low.

The official foreign trade agency ITA/ICE promoted the participation of institutions and buyers from 16 countries, according to ASSOMAC -organizer of the event-.

In relation to last year's fair, there was a 57% increase in the public, highlighting the gradual opening towards international markets, with the exception of those that are part of the conflict in Ukraine, in addition to China.

At the close of the edition, there was a feeling of optimism and confidence in the future, being for its participants, a successful version of SIMAC TANNING TECH. Thus, the internationalization of the exhibition was strengthened with the good results obtained, promoting in turn the differential of sustainability, innovation and digitalization that characterizes it.

During the three days of the fair, ASSOMAC Talks offered a series of debates that covered topics such as sustainability, markets, technology, retailers, traceability, augmented reality, among others.

The talks were attended by various representatives of the sector, representing entities such as APICCAPS (Portuguese Footwear, Components, Leather Goods Manufacturers’ Association), UITIC (International Union of Shoe Industry Technicians) and FDRA (Footwear Distributors and Retailers of America).

At SIMAC TANNING TECH, the proposals of Brazilian exhibitors were also exhibited, in addition to the assistance of representative associations of the suppliers of that country, such as ASSINTECAL (Brazilian Association of Companies of Components for Leather, Footwear and Manufactured Goods). The delegation that had the support of APEX, By Brasil Components, Machinery and Chemicals, was made up of OTB, Formas KUNZ, SystemHaus, NBN, Michelon, Bremm Peck and Tubox Magma. CICB (Centre for the Brazilian Tanning Industry) was also part of the representation.

For its part, BRAZILIAN LEATHER, occupied its own stand where the DESIGN NA PELE project was developed. The initiative was carried out jointly by five national tanneries and five international designers, and unveiled a collection of footwear, leather and bags.

The companies involved were Nova Kaeru, Fuga Couros, Couroquímica, Natur and JBS Couros, complemented by designers from Brazil, the United States, India and Greece, CICB reported.

Technological advances are consolidating rapidly in the footwear and manufacture industry, together with the production of skins and leather.

The trend is the automation and integration of processes that allow greater productivity in terms of volumes and quality, under growing sustainability requirements, where the recovery and recycling of materials is essential in the circular economy model.

The reality marks a greater industrialization in the production of manufactures, relegating artisan elaboration to a very specific segment.

Under these statements, SIMAC TANNING TECH presented systems and equipment with a high degree of automation, through robotization, which respond to sophisticated software that solves different operations with maximum precision, speeding up time and reducing costs. Digitization and interconnectivity make notable progress in the integration of processes.

It is one of the priorities of the new technologies, presented by MAINGROUP through peripheral systems that can be added to the machines to recover and reuse all types of EVA, rubber and polyurethane waste. Thus, an exclusive equipment was exhibited, which after the grinding and pulverization of the waste, is transformed into reusable compounds for the injection of soles. In this way, production is more sustainable and respectful of the environment. The integration of the system starts from the material collection hopper to the extraction of the injected sole, in a fully automated process.

It is the CERIM K 175 model, which, through 6 programmable axes, achieves a high definition in the work profile in different types of footwear, with different tools, depending on the characteristics of the materials. The new DGT digitizer makes it possible to create programs directly on the machine, quickly and simply. Likewise, it allows instantaneous and independent corrections to be made by zones, in the right and/or left shoe. High productivity and self-diagnosis system.

CESARE COLOSIO, leader in woven uppers technology for footwear, exhibited the latest version of its S1M machine -True Argyle- that gives designers the greatest creative possibilities, in knitting systems and application of drawings and colors.

The manufactured products are tubular woven uppers, seamless and with differentiated weft zones, ready for the application of the soles. Due to their versatility, the machines weave complete uppers for different types of footwear: technical, sports, fashion and casual. Starting from the design, the equipment, through exclusive software, programs and automates the entire process, allowing corrections and adjustments, during ultra-fast production cycles and without generating waste.

It was developed by STEMMA -polyurethane injectors- through an integrated system, made up of a new web-app that makes it possible to obtain all production data in real time and remotely, such as injections carried out, work and inactivity times, consumption and material waste, energy demand, etc. The new tool makes it possible to keep process efficiency under control and optimize productivity.