The CONCEPT FACTORY was one of the major attractions at the FIMEC supplier fair in Brazil, where thousands of visitors toured the facility to see firsthand the materials, components, processes, and technologies used in footwear manufacturing. In the latest edition in March 2023, there were 5 production lines, involving the participation of 70 supplier companies and trained personnel who worked continuously during the 3-day event, manufacturing shoes in front of the public.

As an expert in footwear, Luis Coelho's company has been providing consultancy services for 28 years with a team of specialized professionals. They have carried out projects in various countries in Latin America, therefore, they have valuable experience in the sector and are qualified opinions on the present and future of the region's footwear industry.

"Today, due to the challenges in finding skilled labor and the strong global competitiveness, incorporating technology is essential as a fundamental tool to maintain continuity".

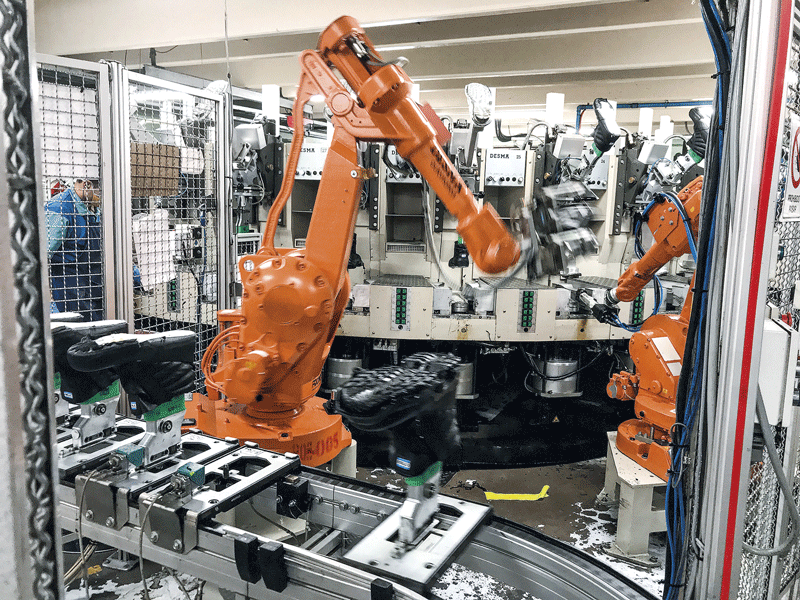

When asked about the growing technification (automation, robotization, etc.) in the footwear industry compared to traditional and artisanal systems, he stated: "I believe there is no incompatibility between the two. Regardless of technology, footwear will always require people and their labor. It largely depends on the size of the company and the market segments it serves. When it comes to high-volume production, where we need efficiency to manufacture in less time, with lower costs and fewer human resources, technology should definitely be incorporated. On the other hand, when it comes to products that necessarily need to be artisanal, with higher added value and lower volume, such as fashion footwear, the search is for intensive and qualified labor. Generally, these types of productions target niche markets".

"In the case of a factory programmed to produce 10,000 pairs of athletic shoes per day, the incorporation of technology must necessarily be considered to achieve greater competitiveness".

Regarding the artisanal production of footwear that may be affected by the processes of technification, he said: "I believe there is room for both. There is space for small and medium-scale artisanal productions as well as high-volume productions. This depends on cultural factors and changes in consumer habits. It is now common to wear casual or sports footwear for work, while for special occasions or formal attire, a more formal and artisanal product of high quality is preferred. I don't think the cultural change will be so strong that we stop using leather footwear, which is the best material for manufacturing".

Regarding the crisis caused by the shortage of labor in the footwear industry, especially in our region, Coelho expressed his opinion: "There are factors related to the past, such as the perception of the industry as marginal and unattractive to potential workers. Without generalizing, there is an idea of disorderly factories with outdated machines, lacking cleanliness and comfort. However, there are others that have changed significantly through new technologies, being more organized, with cleaner and automated processes, and providing greater comfort for employees. It is the responsibility of industrialists to create an attractive environment where growth and development opportunities are offered, along with more appealing salaries".

Among the main recommendations for the Latin American footwear industry, considering its characteristics, he emphasized that "entrepreneurs must educate themselves. The majority of factory owners are former shoemakers. They are people who transitioned from production to starting their own businesses. While they may excel in making shoes, they may lack the capacity and knowledge for administration. It is common to see a factory owner who handles purchasing, production, and sales. However, experience shows that someone who does everything may not be productive. I believe shoemakers should acquire training, take management courses, and access new knowledge that provides a more comprehensive view of their business. Establishing internal organization in factories is essential, followed by setting quality objectives. Then, it is important to define the consuming public and with what product is intended to reach, and in this case it is advisable to focus on a specialty to improve. During my visits to many footwear fairs, I have seen a wide variety of product lines in the same stand, including children's, men's, and women's shoes in different styles. I wonder if productivity can be achieved with such diversity. I believe it is impossible. This implies multitasking workers who do not acquire specific skills, constant changes of machines and tools, and time wasted in model changes, among others. Companies should seek their identity through a product that represents them, with efficient collaborators and an open mindset. Today, the market demands not only quality, design, and cost but also sustainability, which is a growing factor in collective consciousness".

Finally, Coelho shared his views on the export possibilities for Latin American countries. "Beyond Brazil, which has historically had significant international market penetration, followed by Mexico with lower volume, I have no doubt that other countries can generate their own exports, taking into account the diversification observed in the supply points. If we recall the 1990s when China emerged as the giant producer and exporter, Americans and Europeans concentrated 100% of their purchases there. With the pandemic, there was great panic when they found themselves without their suppliers, prompting them to immediately search for alternative sources. That's when they turned back to Brazil, Indonesia, Malaysia, Mexico, Portugal, among others. They learned to diversify their purchases and not rely on a few sources. I believe that in this context, opportunities arise for high-quality leather footwear from Argentina, as well as for Colombia, which has a strong identity in design and manufacturing. The important thing is to capitalize on the inherent values to become more competitive, complemented by the development of an export culture with strict quality controls".