In recent years, the fashion industry has been actively experimenting with bioplastics. The goal is to reduce reliance on fossil fuels by replacing them with natural and renewable raw materials in the production of components and materials. These include corn, sugarcane, sugar beets, and castor oil.

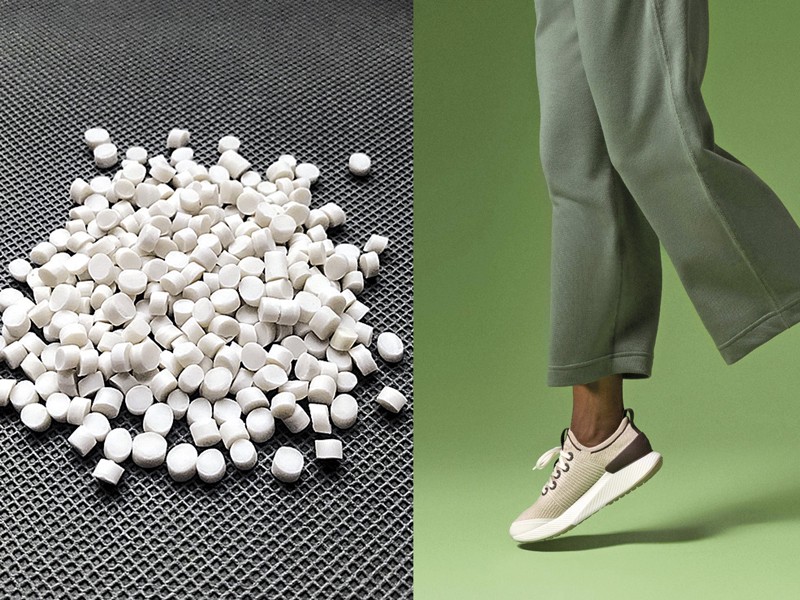

One of the pioneers in researching and developing these alternative raw materials is the Brazilian petrochemical company BRASKEM, the largest producer of thermoplastic resins in the Americas and the world’s leading biopolymer manufacturer. To further its purpose, BRASKEM partnered with the U.S.-based footwear brand ALLBIRDS to create the new GREEN EVA “SweetFoam”, a bio-based and renewable material used in sole production.

It is an EVA (Ethylene Vinyl Acetate) compound derived from sugarcane. During fermentation, it releases polylactic acid, a first-generation polymer with properties similar to polyethylene terephthalate (PET), which can be used to create various components through injection molding.

The footwear industry has adopted this so-called “Green EVA” after ALLBIRDS made the formula open-source, enabling its application in the shoes of prominent brands such as Toms, Timberland, Puma, Adidas, Burberry, Gucci, and Zara, among others. Technical researchers predict that the entire footwear industry will transition to bio-based soles within the next decade.

The new elastomeric polymer developed by BRASKEM, sustainably made from sugarcane (a renewable resource), contributes to reducing greenhouse gases by capturing CO2. The resulting products are similar to rubber in softness and flexibility. “Green EVA” replaces conventional resins without requiring additional investments in plastic processing machinery. It is recyclable and reusable, just like traditional EVA.

This material for shoe soles, derived from the first negative-carbon GREEN EVA, significantly contributes to slowing climate change.

The sugarcane used to produce SweetFoam is sourced from southern Brazil, where it relies on rainfall instead of irrigation. A fully renewable resource that grows quickly while removing carbon from the atmosphere. On the other hand, it is so self-sufficient that when processed, its biomass is used to power the mill and fertilize the following year’s crop. Sugarcane production adheres to rigorous standards that protect people and the environment, with protocols developed by Proforest and Braskem. Farms are audited by third parties.

BRASKEM exports to customers in 100 countries and operates 41 industrial units in Brazil, the United States, Germany, and Mexico.

ALLBIRDS focuses on creating shoes with simple, comfortable, and eco-friendly designs using renewable and recyclable natural materials. By 2025, its goal is to use 75% natural and recycled materials from sustainable sources and reduce the carbon footprint of its raw materials by 25%. Another objective is to decrease the use of raw materials by 25% and innovate with new technologies to enhance the performance and longevity of natural materials.

According to Dr. Ashley Holding, a renowned German chemist and international consultant, it is impossible to make general statements about bioplastics since sustainability credentials vary depending on the raw material, the type of plastic it becomes, where it is produced, and what it replaces.

“Being bio-based doesn’t mean it’s biodegradable, and being biodegradable doesn’t mean it’s bio-based,” explains Holding. “Many fossil-based plastics are biodegradable. In fact, those used mainly in biodegradable packaging are fossil-based. It depends on the chemical structure of the polymer itself, not the raw material it comes from.”

This often leads to confusion among brands and customers. “It’s something material manufacturers present to brands, which may include it in their marketing materials without fully understanding the distinction,” says Holding. “This is a common misunderstanding, and the public may be quite confused if something is marketed as biodegradable, assuming it’s bio-based, or vice versa.” Commercially available bioplastics function like any other plastic. Regarding recycling, bioplastics can be recycled as long as there are already recycling facilities in place to do so.

Sources: Braskem/Allbirds/Ecocult