To determine the properties of a leather, it is necessary to carry out some tests that vary according to its final destination. It is necessary to establish what analysis have to be applied in each case in order to evaluate the physical and chemical properties that the elaboration of the article requires and that regulate the desired behavior of the leather.

The process of selection and acquisition of leathers for the different parts of the footwear, which guarantee proper behavior in the final product, is not an easy task. The variety of footwear typologies is very wide, from children's footwear to safety footwear, with innumerable intermediate models, designs, fashion, accessories, combination of materials, manufacturing processes, etc., which must be taken into account and condition the choice of raw material "leather".

On the other hand, in the market there are leathers differentiated by tanning processes, species, type of finish, etc., which can be used in different parts of the shoe. All these options make up a wide range of possibilities with different specifications that will have to meet different requirements and regulations. In the case of safety footwear, for example, there are requirements and test methods that are standardized according to the IRAM 3610 Standard, which determines the specifications that leather must meet for the different parts of this type of footwear. These specifications are used in the leather purchasing process in the buyer-seller relationship.

For the rest of the footwear, we can find quality recommendations for the assessment of leather at UNIDO, GERIC, Associations of the German Leather and Footwear Industries, INESCOP and the AENOR Technical Committee, among others, which have worked on guidelines of quality for leathers destined to the different parts of the footwear.

These are lists with reference values, useful for evaluating a leather for a given use and may be inappropriate for another, thus demonstrating the relativity of the quality concept.

It should be noted that currently from the Department of Technology for the Production of Leather and Footwear of INTI-Argentina, a technical table of standardization is being worked on at IRAM to establish a national standard that defines the requirements that leather must meet for different parts of the shoe. Different links in the footwear manufacturing chain have been invited to participate through CAIPIC (Suppliers), CIC (Manufacturers), ACUBA and CICA (Tanneries) and AAQTIC (Technicians), among others. The objective is to reach a consensus among the parties involved, the tests, methods and standard reference values to evaluate the Physical-Mechanical and Chemical properties, thus defining the technical specifications of the leathers to be used in each part of the footwear (upper, tongue, lining, midsole, etc.) and ensuring the desired behavior.

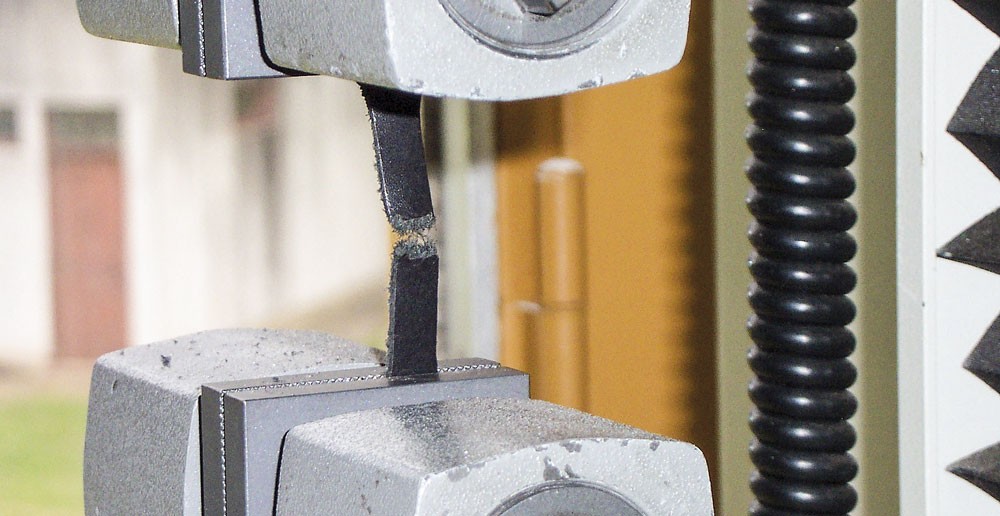

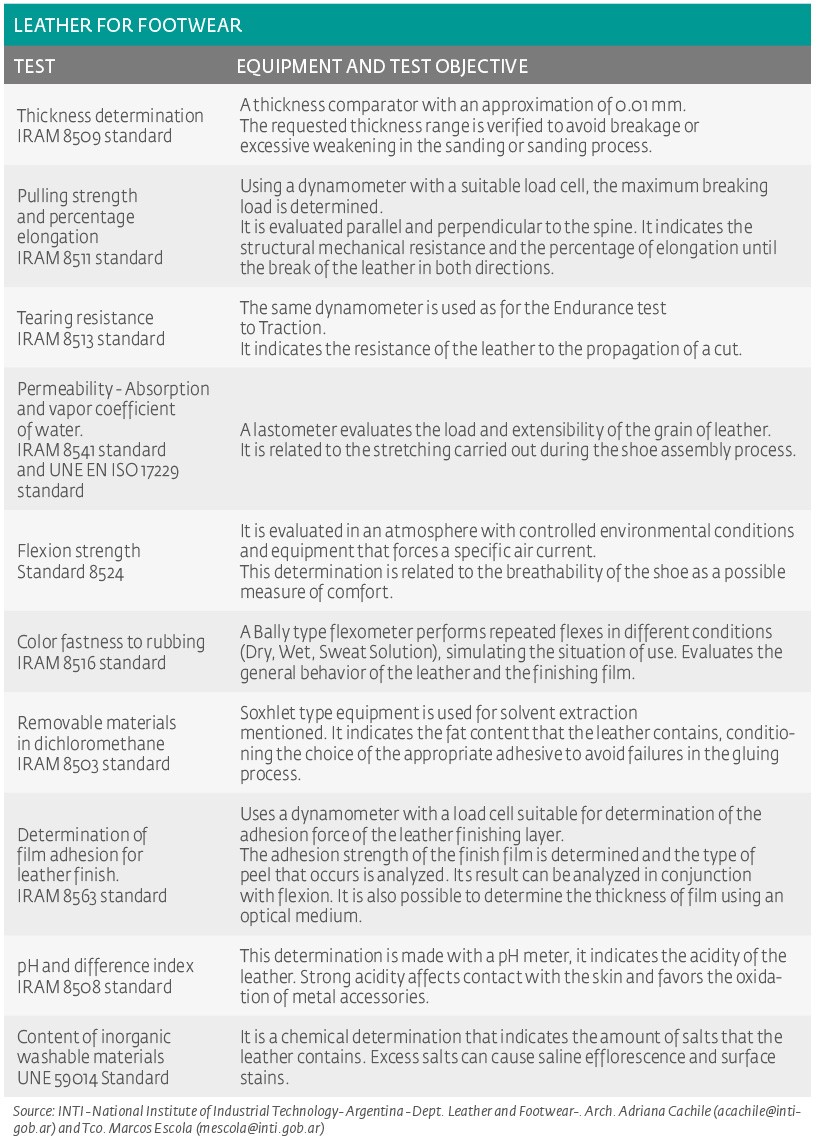

Below are some recommended tests and methods to analyze the leathers for the different parts of the shoe, the equipment used and what is evaluated in each of them:

RELATED ARTICLE: