The global chemical company HUNTSMAN presented last July the details of a new range of additive manufacturing materials developed in urethanes, to meet the emerging needs of the 3D printing sector.

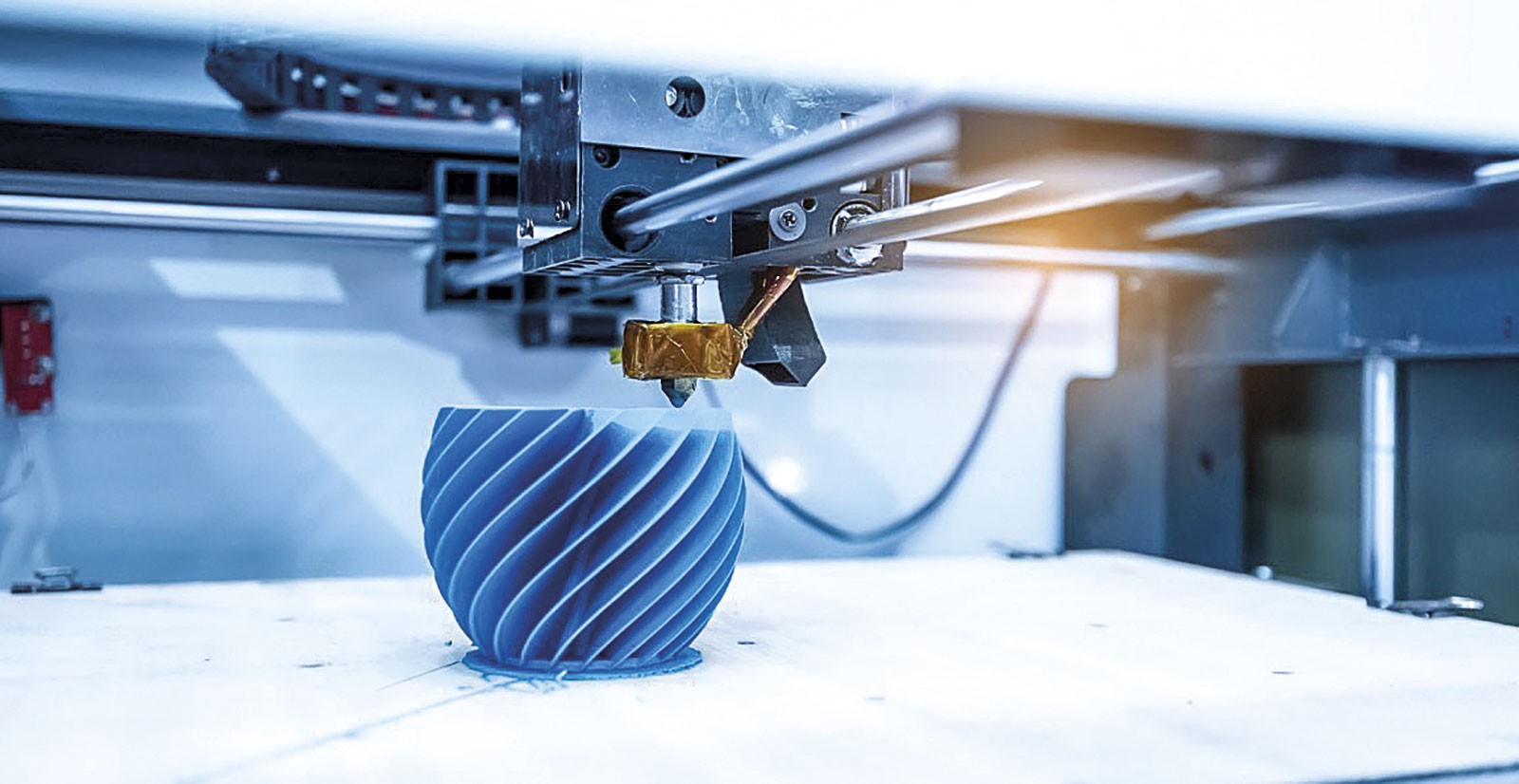

The IROPRINT® additive production platform contains three different types of urethane-based materials (resins, powders and filaments), which can be printed in 3D using various additive manufacturing methods such as stereolithography (SLA), high-speed sintering (HSS ) and fabrication with molten filament (FFF).

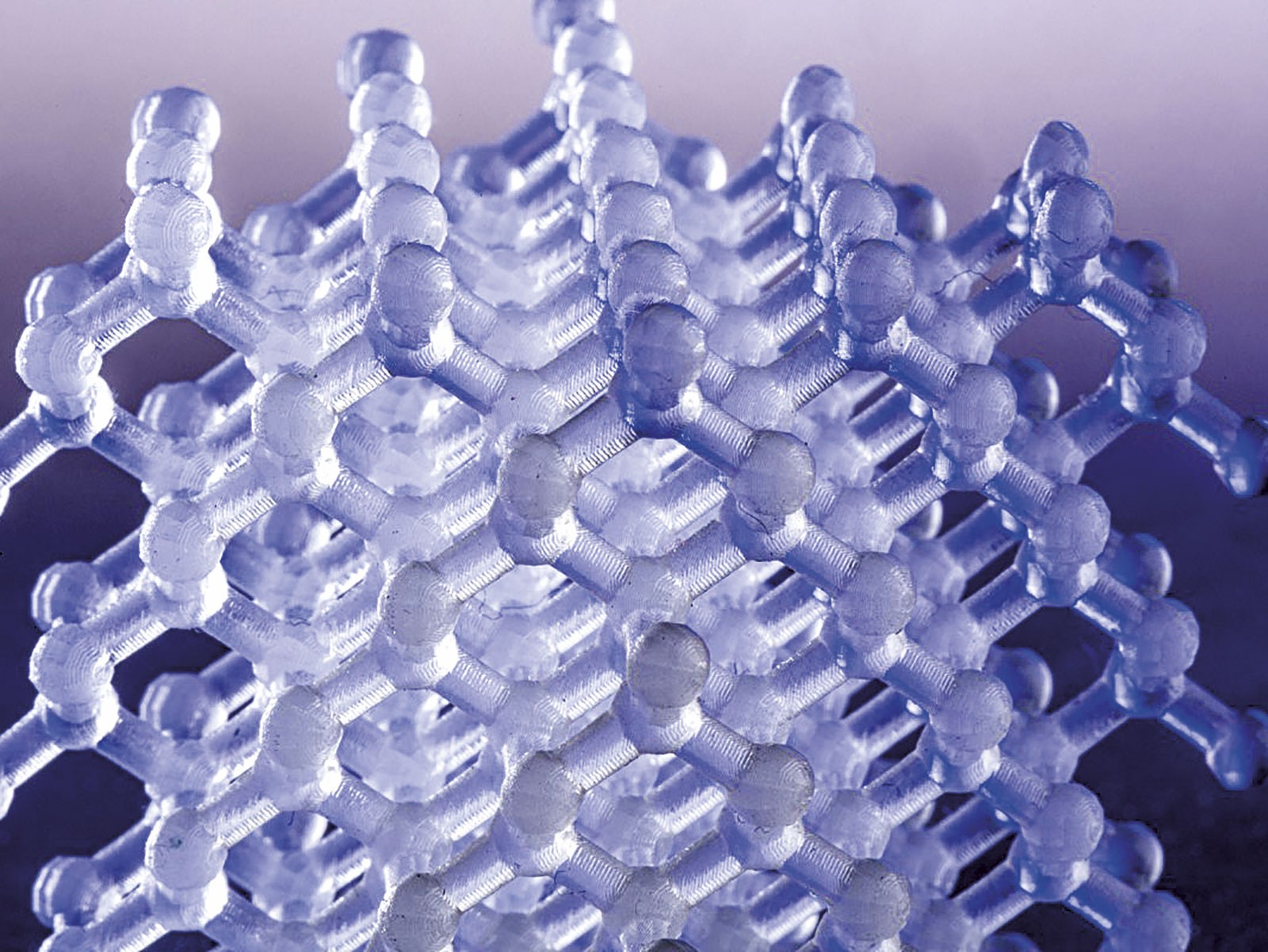

Initially, the range of soft and flexible IROPRINT® additive manufacturing materials was launched for the global footwear and sports sector, which uses 3D printing to produce both custom and mass-produced footwear.

In addition to printing (manufacturing) prototypes and finished products, the system allows different parts and components of footwear.

Actually, IROPRINT® additive manufacturing platform includes three product lines that have been optimized to work with the main 3D printing techniques preferred by shoe manufacturers.

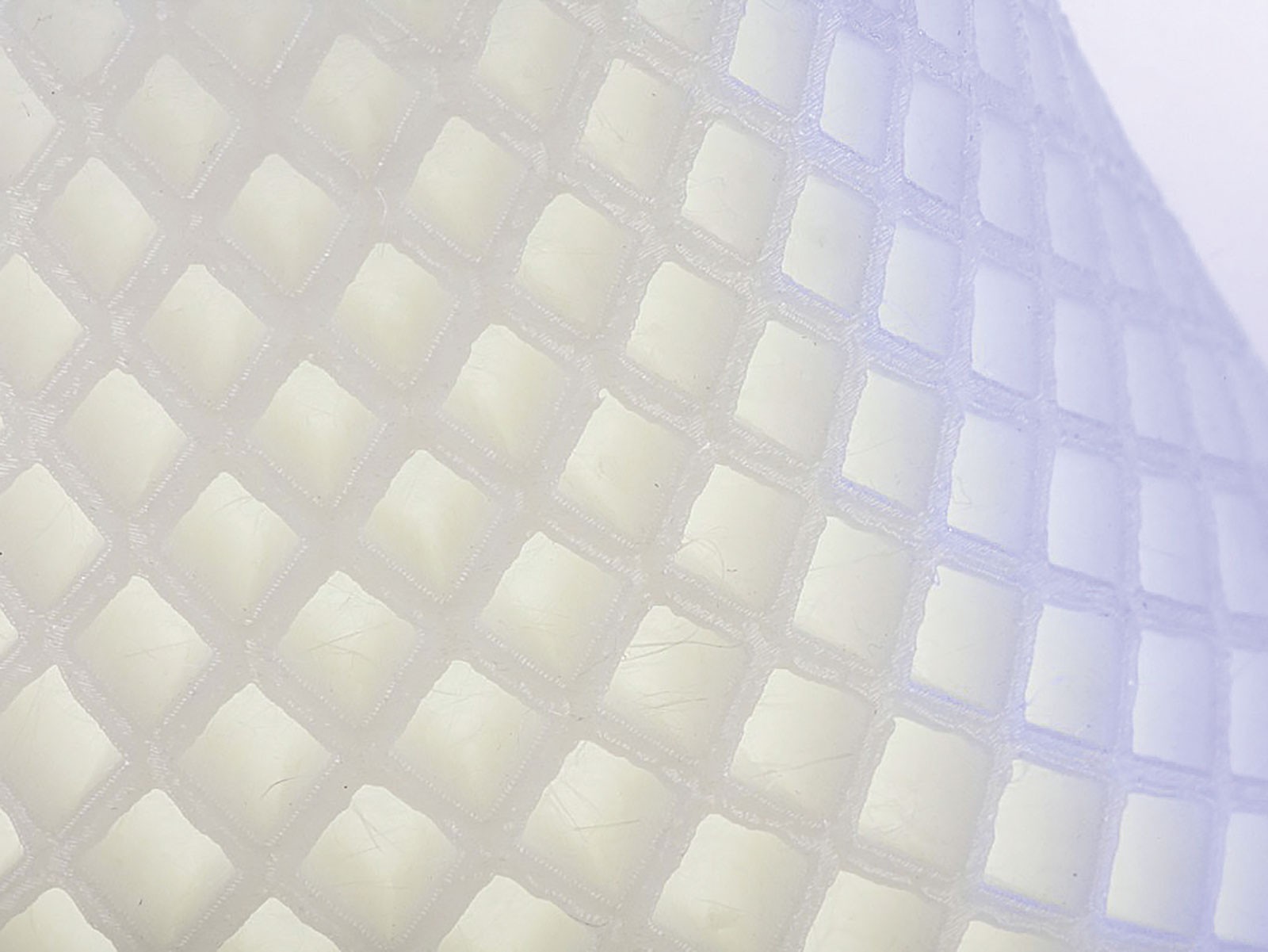

• IROPRINT® R resins are a range of liquid resin systems with a single component, soft and durable, that can be printed in 3D using SLA, digital light processing (DLP) and other radiation drying methods.

• For companies searching for 3D printing with powder-based materials, IROPRINT® P powders are a line of high performance thermoplastic polyurethanes (TPU) for HSS printing formats.

• IROPRINT® F filaments are a collection of high-performance TPU materials with a constant diameter and are designed for use in the manufacture of molten filament (FFF) and other extrusion-based printing techniques.

The three IROPRINT® additive manufacturing product lines have been optimized for the production of footwear components and are easy to use and print, providing advanced abrasion, elongation and tear resistance. For printing methods with radiation drying, such as SLA or DLP, IROPRINT® R resins also offer a long service life and fast drying capabilities.

In the preliminary presentation of K 2019, the largest fair of plastics and rubbers in the world to be held in Düsseldorf, Germany, from October 16th to 23rd, Stephane Peysson, director of Global Business Development of HUNTSMAN Polyurethanes, said: “Our team Innovative incubation has worked closely with end users and industry leaders to develop our portfolio of IROPRINT® additive manufacturing products. We have carefully reviewed the ideal characteristics of a good 3D printing material and the gaps in the market to date. The new range of functional 3D printing materials, durable but at the same time softer, are technologically independent and cheaper as easy to print, whatever your preferred production technique. ”

"It is a good time to participate in the additive manufacturing market, as estimates suggest that, by 2024, the sector will grow by more than 20%," he concluded.