The renowned Swiss sports shoe brand ON, a pioneer in the production of soles with transverse holes, has introduced a completely new aesthetic and design feel.

Now, through meticulous research and development, ON has launched an innovative footwear construction system that produces high-performance uppers using a revolutionary one-step process.

The system, called LightSpray ™, creates an ultra-light, flexible, and breathable one-piece upper that is not manufactured conventionally. Instead, it is sprayed onto a last, producing 75% less carbon emissions than other running shoes and reducing waste.

The new technology paves the way for a sustainable future and faster local production.

The manufacturing of this sneaker is automated using a robotic arm and can be completed in just 3 minutes.

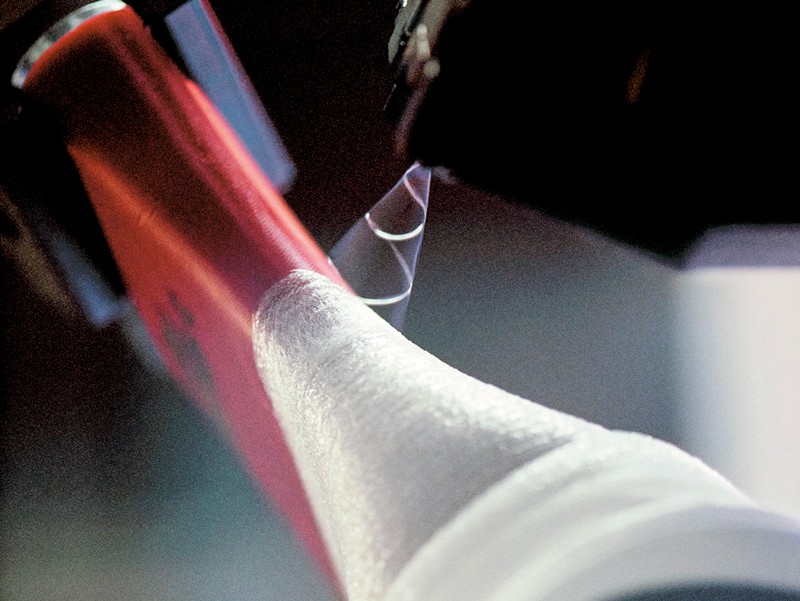

It is essentially a 3D printing technique with a constant flow of an exclusive continuous thermo-bioplastic foam helicoidal filament, with integrated thermal fusion, forming an engineered structure that bonds to the midsole sidewall without the need for adhesives.

The robotic arm carefully creates the "computer-optimized sole" using a material the company calls Double Helion™ HF hypofoam. The foam is made of over 40% bio-based plastics.

The robot arm sprays the foam onto a mold or last. The material then solidifies, retaining the shoe's shape as a single solid piece. The final shape stretches to fit the foot, eliminating the need for laces.

With LightSpray™, ON has not only revolutionized the look, feel, and functionality of a product but also the construction, design, and development process. Traditional modeling is replaced by computer-assisted design and robotic programming. This way, each part of the LightSpray™ structure can be tailored to specific requirements, allowing for rapid prototyping and turning ideas into products in just hours.

The upper material weighs only 30 g, while the entire sneaker weighs 170 g.

The ultrathin LightSpray™ upper is precisely designed to mold to the foot, with no seams or laces, resulting in an exceptionally lightweight sneaker.

The midsole consists of two layers of Helion™ HF hypofoam, ON’s ultrasensitive Pebax formula, providing cushioning and high energy return.

A rigid, pre-molded carbon speedboard or plate embedded in the foam ensures optimal propulsion with each step.

The adhesive-free LightSpray™ system enables minimal construction of the Cloudboom Strike LS, with no insole or strobel, keeping direct contact with the Helion™ HF hypofoam for minimal energy loss.

The hermetic seal around the ankle prevents dirt and particles from entering the shoe.

Although the new shoe is initially intended for athletes, the system is expected to be applied to other lines of sports shoes from the brand.

RELATED ARTICLE:

- Swiss origin. ON CLOUD sneakers, a global success