Technological advancements in footwear production, especially in contrast to traditional manufacturing systems, are irreversible, and as such, are profoundly transforming the activity.

We refer in particular to new equipment and materials that enable the production of printed or injected single-piece shoes, requiring less manual labor and reduced production time. In comparison, costs are lowered, and new designs are being introduced with notable success in fashion segments.

These are shoes that offer good comfort, low weight, flexibility, functionality, and ergonomic performance.

While printed footwear and components initially emerged in prototyping, industrial-scale production systems are now being developed.

One of the most recent product launches came from NIKE, a leader in sports and casual footwear, which unveiled its exclusive NIKE Air Max 1000, entirely produced using 3D printers.

It all began with a collaboration between NIKE and ZELLERFELD, a company specializing in futuristic design with expertise in high-precision 3D printing, using TPU (thermoplastic polyurethane), a highly flexible, durable, and recyclable material. The result is a seamless shoe or sneaker, free of adhesives, offering a glove-like fit. Moreover, leftover material is reused for new shoes, making them environmentally friendly.

The process begins with a digital design that includes every detail of the shoe, from the sole’s texture to how the upper should flex. That design is sent to a 3D printer, which builds the shoe layer by layer using TPU filament.

Rather than going through stitching, gluing, and assembly stages, the shoe comes out ready to wear. It can literally be imagined as coming straight from the printer onto your foot.

Another advantage of this system is that it enables on-demand manufacturing, with less waste and total customization.

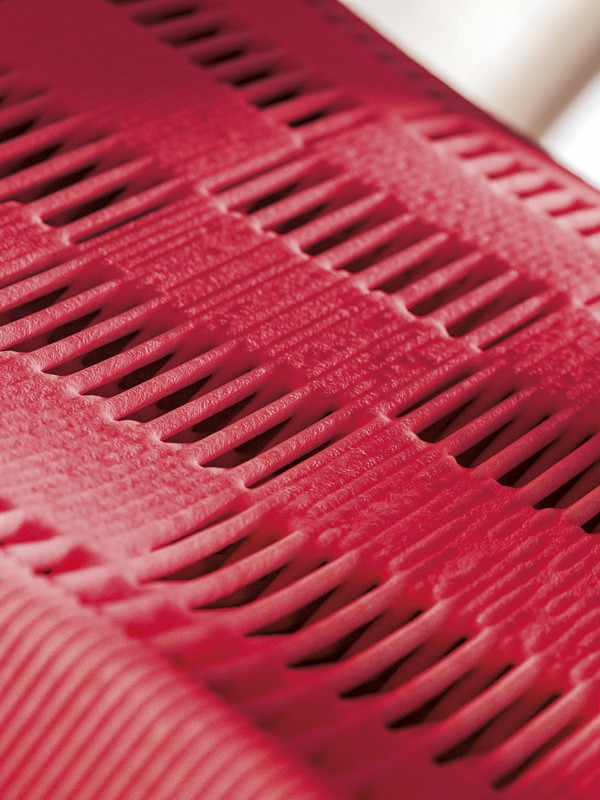

Aesthetically, these are futuristic and cutting-edge products, sculptural in form and laceless. Visual contrast comes from the combination of smooth and textured prints. The smooth areas appear on the toe cap and midfoot, while the textured ones mimic carbon fiber in the collar, lower half, and toe cap.

In the heel window, there is an air chamber, which is not 3D printed.

The blend of layers with varying densities and textures allows the outsole to remain firm and supportive, while the upper parts of the shoe are more flexible and comfortable, enabling easy slip-on functionality without laces.

NIKE is not alone in experimenting with 3D-printed footwear. Its competitor ADIDAS is also doing so, marketing sneakers with printed midsoles. However, like NIKE, the German brand has also created fully 3D-printed shoes, including its latest Climacool24 model, which debuted in October of last year.