8. Augmented reality as an opportunity to instruct personnel in production and/or maintenance.

10. The need to reorganize the so-called “last tranche” in sales channels to the final consumer and spaces related to distribution in that area.

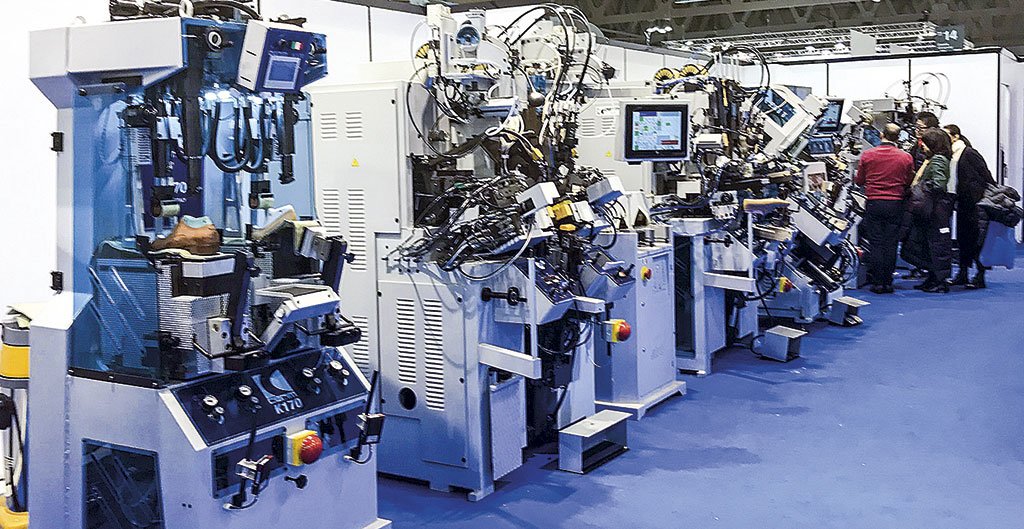

The points listed open the era of 4.0, the fourth industrial revolution based on the interconnection between machines and companies in the chain and the exchange of digital data. A complex challenge, especially in industrial areas of labor intensive as the footwear production.

"The digital information of companies is not only a faster way to do what we do, but a broader concept, which means changing orientation and mentality, essential to gain competitiveness."

"The sector is on the move and this is the merit of every small business, which, day by day, carries out a constant work of technological search for products and processes."

Given the increasing sensitivity of the market to environmental issues and greater productive efficiency, from an energy point of view, less polluting and respectful of ethical and safety standards, ASSOMAC, the Italian association of manufacturers of machines for the leather, footwear and manufactures industry, presented at the last SIMAC-TANNING TECH in Milan, its “GREEN LABEL”.

It is a voluntary commitment of companies in the sector to inform their customers of the parameters of efficiency and reduction of environmental impact of each of their machines. Such certification is carried out by examination through CFP (carbon footprint) with the LCA (Life Cycle Assessment) calculation method.

At the end of the presentation, the president of ASSOMAC said that “traceability, sustainability, transparency and environmental compatibility are essential requirements that we cannot ignore. Our challenge is to find innovative solutions to relate the production process to environmental sustainability, which is not only an element of excellence, but also of competitiveness, in an increasingly demanding market in this matter ”.