The new ADIDAS sneaker is the result of 18 years of collecting and analyzing data from athletes, monitoring races on treadmills and observing the impact of the feet on the ground during each stride.

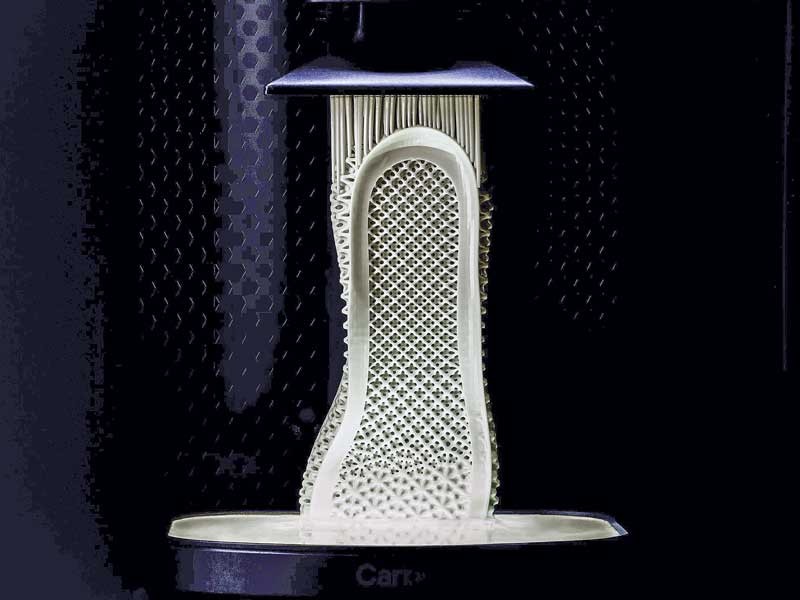

Its main innovation is the exclusive midsole made using 3D printing technology, which reduces braking forces and transforms the impact of the foot against the ground into an impulse to take off, with a smooth transition, less friction and unique performance.

It is through Digital Light Synthesis™ technology, exclusive of Carbon/USA, which through a chemical process uses light and oxygen to create a 3D object (midsole) transforming liquid into solid. Based on biomechanical tests carried out at the University of Calgary and evaluating five million possible lattice structures, the design of cells in the form of bows that are compressed and enhance impulse capacity was obtained.

The midsole of the ADIDAS 4DFWD converts vertical impact into forward horizontal movement to create a fluid and continuous transition.

Defying the laws of physics, these jogging or running shoes ensure that each time the foot comes into contact with the ground, it does not suffer the braking forces that interrupt the forward movement and the fluidity of the race.

The fundamental concept of these soles is to transform the energy of the impact into momentum.

In comparative tests carried out with EVA foam soles and similar, the ADIDAS 4DFWD reduced the braking forces, which are produced when the foot hits the ground, by an average of 15%, and increased the cushioning generated during the mechanical tests carried out with vertical loads by 23%.

The “Continental” outsole or rubber bottom sole, guarantees greater grip on any terrain and greater stability in each movement.

The one-piece uppers, made with the Primeknit digital knitting system, with 50% recycled polyesters and technical mesh, allow maximum comfort, of a seamless enveloping structure, which ensures greater support and adjustment of the foot.

RELATED ARTICLE:

- The Midas King Messi boosts Inter Miami and Adidas business