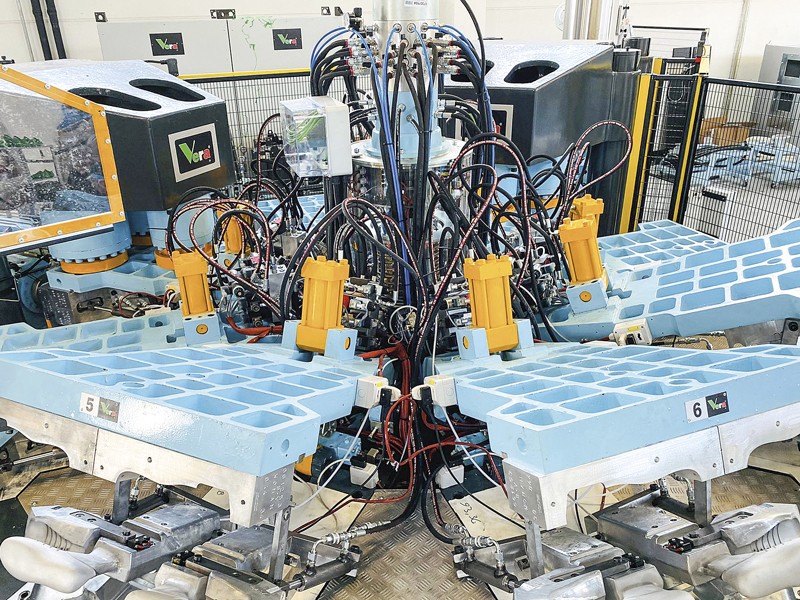

It is applicable to all types of old or disused injection machines used for the production of various lines of footwear, soles and diverse components.

The new service offered by the Italian company BRSERVICE VERA, led by Nicola Brunello and Davide Silvestrín, renowned technicians with extensive experience in the field, achieves the complete renovation and modernization of obsolete injection machines by replacing used components with new state-of-the-art electronics. In addition to implementing the innovative ENERGY SAVING VERA® system, which allows energy savings of 50% compared to conventional machines.

The company has the capability to provide personalized retrofitting services tailored to the needs of each client, ensuring that old injectors can operate with improved performance, efficiency, and lower energy costs.

This alternative allows existing equipment to be upgraded with new technological advancements at a much lower cost, avoiding significant investments.

The introduced changes to the machines significantly enhance the industrial process, with the main advantages being increased productivity and higher quality in the final product.

The services offered cover machines from different brands that work with thermoplastics such as PVC, TR, TPU, expanded materials, EVA, etc., and polyurethanes.

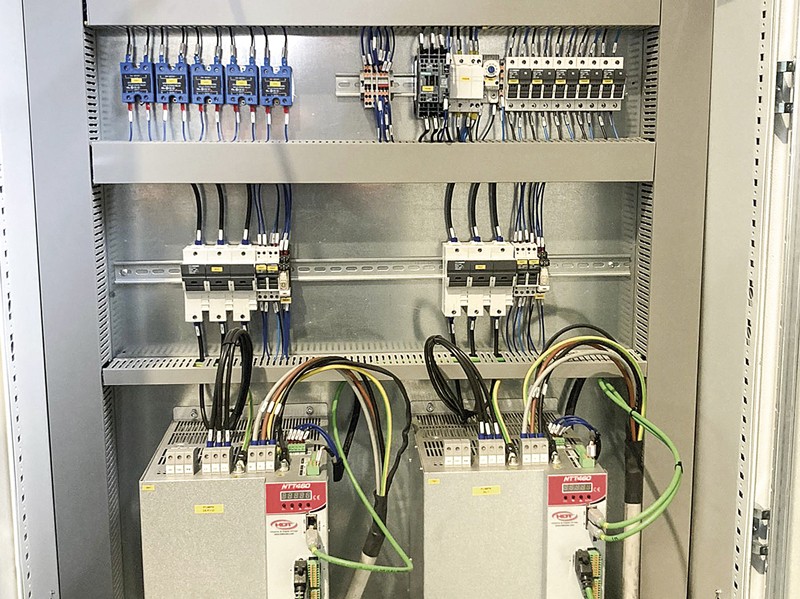

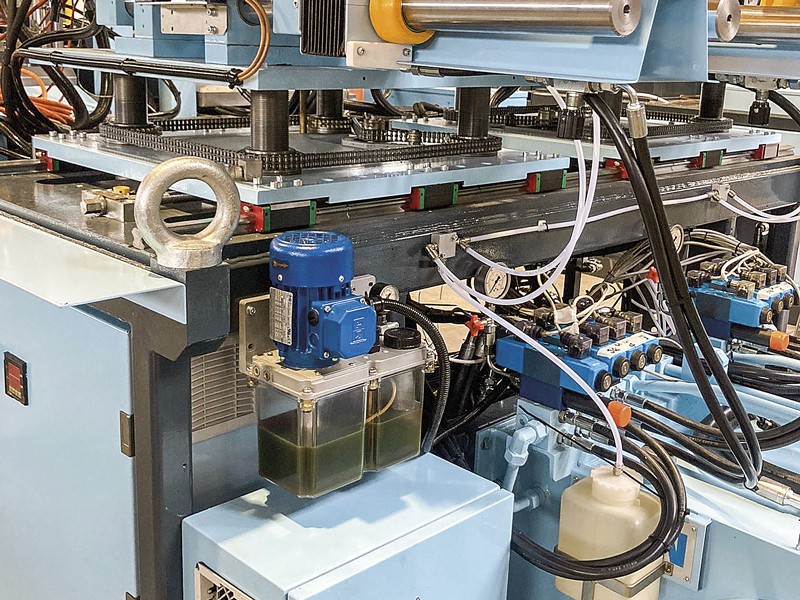

Among the main tasks for equipment updates, the following stand out: disassembling the mechanical part and injectors; replacing the mold carrier column and connecting rod control; replacing the PLC and PC with the latest generation software to control and monitor all machine parameters; replacing hydraulic pipes and modifying the hydraulic unit to install the Energy Saving Vera® system.

Factories and industries can get in touch and send their inquiries to: info@verasavesolution.com, tel. +39 049 2611487, or visit www.verasavesolution.com.