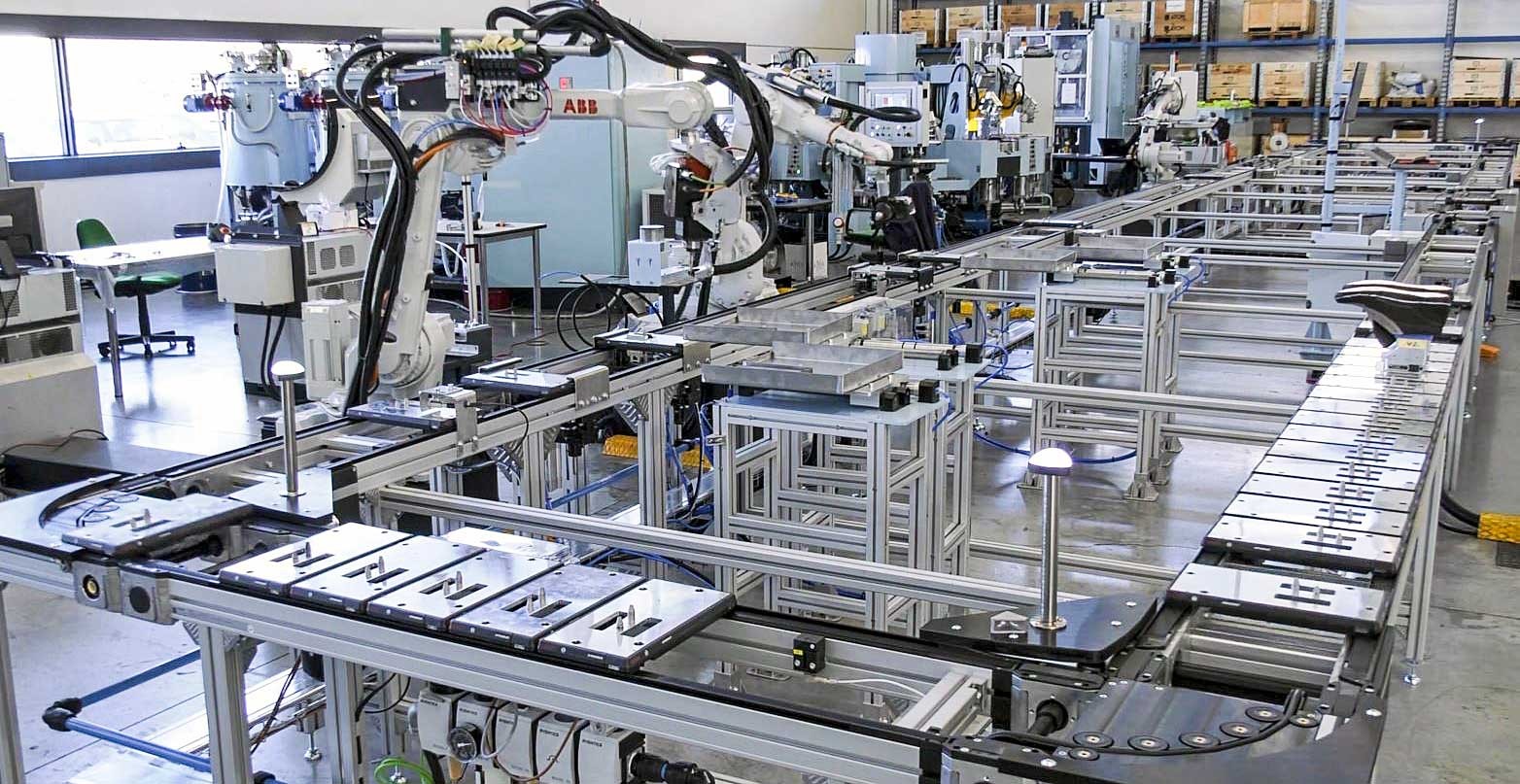

In the latest edition of SIMAC-TANNING TECH, the technology event for footwear and manufactures held in Milan, Italy, MAIN GROUP TECHNOLOGIES brought the factory to the fair.

It did so through a streaming connection activated on demand, through which it was possible to see the latest proposals of the company directly from its establishment in Santa Maria di Sala, Padova.

The event was a tangible sign of MAIN GROUP's vocation for technological innovation.

Research and development work focused on applications for automation, essential for manufacturing plants to be more productive and configured, to ensure their highest functionality and performance in terms of quality and quantity.

For MAIN GROUP automation represents an essential element for all future projects related to FOOTWEAR sector. Thanks to new technologies, automation makes it possible to exponentially improve the quality of finished products, making it possible to obtain results that would be impossible to match with a manual production process.

Furthermore, thanks to lastest generation of automation, it is possible to increase the plant's efficiency index -OEE (General Equipment Efficiency) - significantly, achieving greater productivity of the machines.

Through the Research and Development Division, the company continues to work on new projects about various solutions for the automation of last generation.

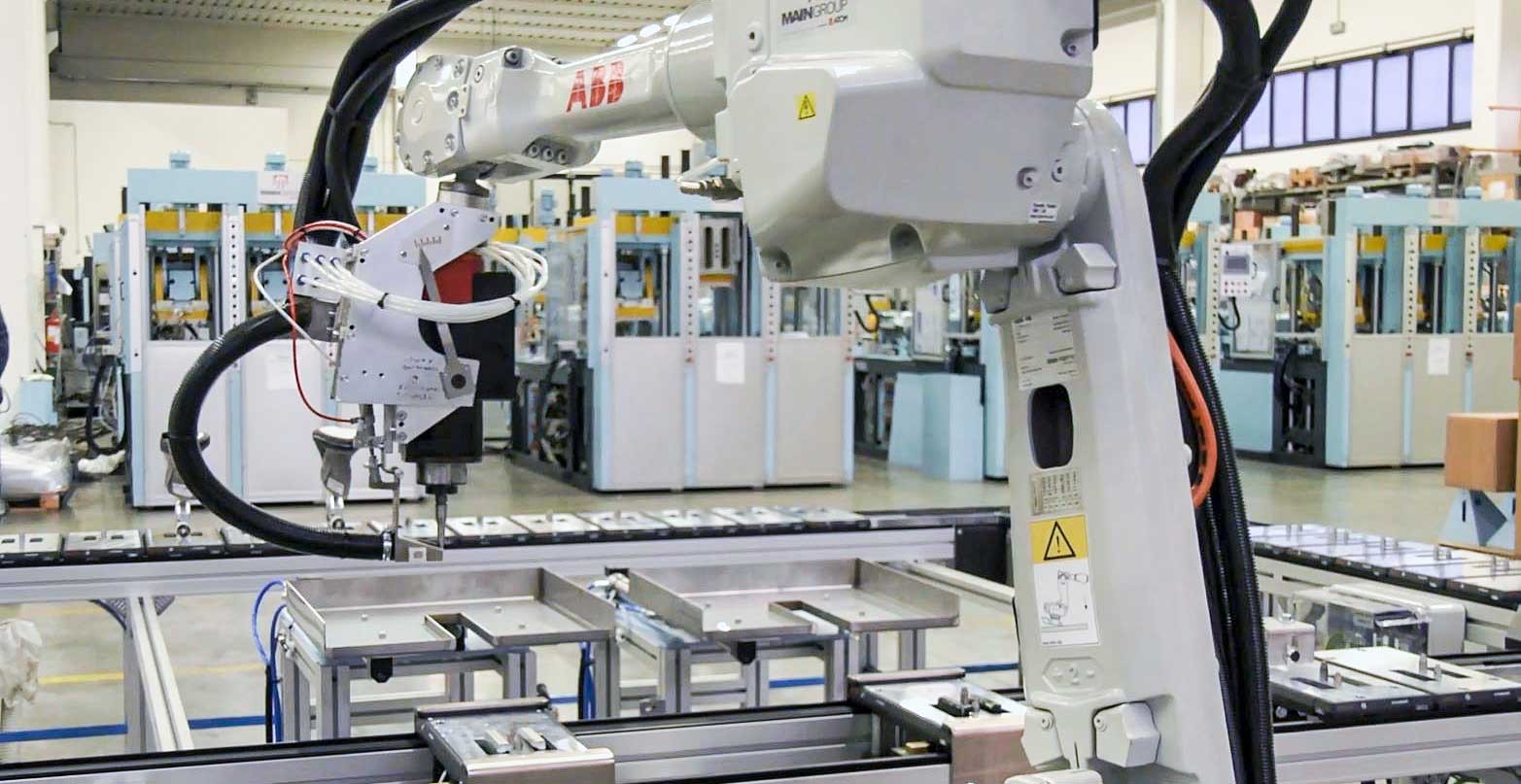

Robots, for example, which have new software and a simplified operator interface, allow management of:

New vision systems make it possible to control quality of finished product and special events occurred during the production process. In this way, the system continuously registers and processes all necessary data to guarantee immediate quality of finished product and provide essential elements for diagnosis of production, interconnected according to the paradigms of Industry 4.0.

RELATED ARTICLE:

MAIN GROUP acquired TECHNETRONIC, leader in automation and robotics